-

Espacio en blanco de PCD

-

Máquina de pulir de PCD

-

Herramientas de pulido de PCD

-

Cortadora del laser de la fibra del CNC

-

Máquina de grabado del laser de la fibra

-

Máquina que suelda del vacío

-

Espacio en blanco de PCBN

-

Diamond Grinding Wheels

-

Diamond Dressing Stone

-

Goma que suelda del vacío

-

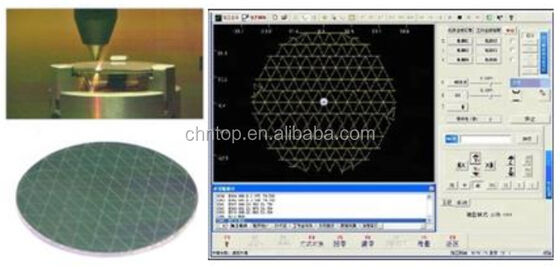

Corte del laser de PCD

-

PCD que suelda

-

Pulido de PCD

-

StevenCHN-TOP ofrecen servicio muy bueno y los productos para ayudarnos mucho

StevenCHN-TOP ofrecen servicio muy bueno y los productos para ayudarnos mucho -

S.N. SharmaLa máquina de CHN-TOP me ayuda a mejorar mi imprresion para las máquinas chinas

S.N. SharmaLa máquina de CHN-TOP me ayuda a mejorar mi imprresion para las máquinas chinas -

Mike¡Los mejores productos con el mejor precio, CHN-TOP bien hecho!

Mike¡Los mejores productos con el mejor precio, CHN-TOP bien hecho!

Cabezal de corte Raytools de Suiza para máquina láser CNC de fibra, que proporciona precisión de repetibilidad de más o menos 0,02 mm, optimizado para el corte de chapa metálica.

Éntreme en contacto con gratis las muestras y los vales.

whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Si usted tiene alguna preocupación, proporcionamos ayuda en línea de 24 horas.

x| Function | Cutting Metal Materials | Lasertype | Fiber Laser |

|---|---|---|---|

| Repeatability Accuracy | ±0.02mm | Cnc Or Not | CNC |

| Focus System | High Resolution Laser Sensor (optional) | Working Speed | 8m/ Minute |

| Transmission Mode | Rack And Pinion | Cutting Head | Switerland Raytools |

| Resaltar | Cabeza de corte por láser de fibra de Raytools,Cortador láser de chapa de metal CNC,Máquina de corte láser de alta precisión |

||

Descripción del producto:

La máquina de corte por láser de fibra CNC es una solución de corte industrial de última generación diseñada para ofrecer una precisión y eficiencia sin precedentes en la fabricación de metales.Diseñado con tecnología avanzada, esta máquina es ideal para una amplia gama de aplicaciones de corte, desde láminas finas hasta placas metálicas más gruesas, lo que la convierte en una herramienta indispensable en entornos de fabricación modernos.Su construcción robusta y sus características innovadoras aseguran un alto rendimiento, fiabilidad y facilidad de uso, lo que permite a las empresas lograr resultados superiores con un mínimo de tiempo de inactividad.

Una de las características destacadas de esta máquina láser de fibra CNC es su excepcional precisión de repetibilidad de ± 0,02 mm. Este alto nivel de precisión garantiza que cada corte sea consistente y exacto,que es crítico para las industrias que requieren tolerancias estrictas y diseños complejos. Ya sea que produzca componentes para automoción, aeroespacial, electrónica o para fines decorativos,La precisión de la máquina garantiza que los productos terminados cumplan con los más altos estándares de calidad sin necesidad de un extenso posprocesamiento.

En el corazón del cortador láser de fibra CNC está un potente servomotor suministrado por Schneider, una marca reconocida mundialmente conocida por su fiabilidad y rendimiento.El servomotor Schneider proporciona un control de movimiento suave y precisoEste motor mejora la capacidad de respuesta y la estabilidad de la máquina.contribuyendo a una calidad de corte superior y velocidades de producción más rápidasLa integración de este servomotor de primera calidad refleja el compromiso de la máquina de ofrecer un rendimiento de grado industrial.

La máquina de corte por láser de fibra CNC se especializa en cortar varios materiales metálicos, incluidos el acero inoxidable, el acero al carbono, el aluminio, el cobre y el latón.Sus capacidades de la máquina de corte de diamantes láser le permiten manejar tareas de corte detalladas y delicadas, así como carreras de producción de gran volumenLa tecnología láser empleada no sólo es muy precisa sino también eficiente, reduciendo el desperdicio de material y minimizando la distorsión térmica.Esto hace que sea una solución respetuosa con el medio ambiente y rentable para talleres de metalurgia y plantas de fabricación.

Para alimentar la máquina se requiere una fuente de alimentación de 380 V de tres fases que opera a 50 Hz o 60 Hz, lo que garantiza la compatibilidad con los estándares mundiales de energía industrial.Esta demanda de energía soporta los altos requisitos de energía de la fuente de láser de fibra y el sistema de servomotorLa entrada de potencia estable ayuda a mantener una calidad de corte constante incluso durante ciclos de producción prolongados,que lo hace adecuado tanto para operaciones de fabricación a pequeña como para operaciones a gran escala.

El modo de transmisión de la máquina de corte por láser de fibra CNC se basa en un mecanismo de rack y piñón.proporcionando un movimiento lineal suave y preciso a la cabeza de corteLa transmisión de rack y pinion mejora la capacidad de la máquina para mantener velocidades constantes y precisión de posicionamiento, que es vital para producir cortes de alta calidad.Este tipo de transmisión es más fácil de mantener y menos propenso a reacciones negativas en comparación con otros sistemas, reduciendo los costes de mantenimiento y el tiempo de inactividad de la máquina.

En general, este cortador láser de fibra CNC representa una mezcla perfecta de tecnología de vanguardia y diseño práctico.Ofrece a los fabricantes una herramienta versátil y fiable capaz de manejar una amplia variedad de tareas de corte de metales con una precisión y velocidad excepcionalesYa sea que busque una máquina de corte de diamantes láser para diseños intrincados o una máquina láser de fibra cnc robusta para producción de gran volumen,Este producto ofrece un rendimiento excepcional que cumple y supera las expectativas de la industria..

En resumen, la máquina de corte por láser de fibra CNC se destaca por su precisión de repetibilidad precisa de ± 0,02 mm, integración de servomotores Schneider, capacidad para cortar diversos materiales metálicos,demanda de potencia de 380 V en tres fasesEstos atributos lo convierten en una excelente inversión para los fabricantes que buscan mejorar sus capacidades de producción, mejorar la calidad del producto,y aumentar la eficiencia operativa general.

Aplicaciones:

El cortador láser de fibra CTSTC ZT-JGQG6S / E es una máquina CNC de láser de fibra de última generación diseñada para satisfacer las diversas necesidades de las aplicaciones industriales y de fabricación modernas.Con su avanzada certificación CE, este láser de fibra CNC ofrece fiabilidad y seguridad, garantizando el máximo rendimiento en diversos escenarios de corte.la máquina proporciona un funcionamiento preciso y fácil de usar, por lo que es ideal tanto para operadores experimentados como para los recién llegados al campo.

Esta máquina de corte por láser de fibra está equipada con la cabeza láser de seguimiento automático Swiss Raytools, que garantiza una calidad de corte constante en superficies irregulares.el sistema de enfoque del sensor láser de alta resolución opcional mejora la precisión y la eficiencia del corteLa cabeza de corte, de origen suizo Raytools, garantiza además un rendimiento superior y una larga vida.lo que lo convierte en una opción confiable para las necesidades de producción a largo plazo.

El láser CNC de fibra se utiliza ampliamente en varias ocasiones de aplicación, como talleres de fabricación de metales, fabricación de piezas de automóviles, industria electrónica y fabricación de modelos arquitectónicos.Su capacidad para cortar con precisión el acero inoxidableLa fabricación en masa de este tipo de productos, que incluye el acero, el aluminio, el cobre y otros materiales metálicos, lo convierte en una herramienta indispensable en estos campos.Este cortador de láser de fibra se adapta perfectamente a diferentes escalas de producción y tipos de materiales.

En escenarios industriales donde la velocidad y la precisión son críticas, la máquina CNC de láser de fibra CTSTC brilla al reducir el desperdicio de material y mejorar la productividad.Su diseño robusto y su embalaje en una caja de madera contrachapada robusta garantizan un transporte seguro y una entrega en 45-60 díasCon una cantidad mínima de pedido de una sola unidad y términos de pago a través de TT, las empresas de todos los tamaños pueden acceder a esta tecnología de vanguardia con facilidad.

En general, el cortador láser de fibra CTSTC ZT-JGQG6S/E es perfectamente adecuado para los fabricantes que buscan precisión, eficiencia y confiabilidad en sus operaciones de corte láser de fibra.Si se utilizan para aplicaciones industriales pesadas o proyectos artísticos detallados, esta máquina láser CNC de fibra ofrece resultados excepcionales, por lo que es un activo valioso en cualquier entorno de corte.

Personalización:

CTSTC ofrece servicios integrales de personalización de productos para la máquina de corte láser de fibra CNC modelo ZT-JGQG6S/E, diseñada para satisfacer sus necesidades industriales específicas.Nuestra máquina de corte de diamantes se puede adaptar con un sistema de enfoque de sensor láser de alta resolución como una actualización opcional para mejorar el rendimiento de corte de precisión.

Certificado con CE, este cortador láser de metal cnc garantiza un funcionamiento confiable y seguro.La máquina funciona con una demanda de energía de tres fases 380V / 50Hz / 60Hz y cuenta con un servomotor Schneider y un sistema de control de la marca Cypcut, proporcionando una velocidad de trabajo estable y eficiente de hasta 8 metros por minuto.

Aceptamos una cantidad mínima de pedido de 1 unidad, con los detalles de embalaje asegurados en una caja de madera contrachapada resistente para garantizar la entrega segura..Ya sea que necesite una máquina de corte de diamantes para metal u otros materiales, CTSTC se compromete a personalizar la máquina de corte láser de fibra CNC según sus especificaciones exactas.

Apoyo y servicios:

Nuestra máquina de corte por láser de fibra CNC está diseñada para ofrecer una alta precisión y eficiencia para varias aplicaciones de corte de metales.Ofrecemos soporte técnico y servicios completos.

Nuestro equipo técnico experto ofrece asistencia con la configuración de la máquina, la guía de operación y la solución de problemas para ayudarle a maximizar la productividad.Ofrecemos manuales detallados y recursos en línea para facilitar la comprensión y el mantenimiento del equipo..

Los servicios de mantenimiento regular están disponibles para mantener su máquina de corte con láser de fibra CNC funcionando sin problemas.y inspección de componentes críticos para evitar el tiempo de inactividad.

En caso de problemas técnicos, nuestro personal de soporte está listo para proporcionar diagnósticos y soluciones remotos.Ofrecemos visitas de servicio in situ por técnicos certificados para restaurar rápidamente el funcionamiento de la máquina.

También ofrecemos programas de capacitación adaptados a las necesidades de su personal, asegurándonos de que sean expertos en operar y mantener la máquina de corte por láser de fibra de manera segura y efectiva.

Nuestro objetivo es apoyar su negocio con un servicio confiable y receptivo, ayudándole a lograr los mejores resultados de su máquina de corte por láser de fibra CNC.